Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

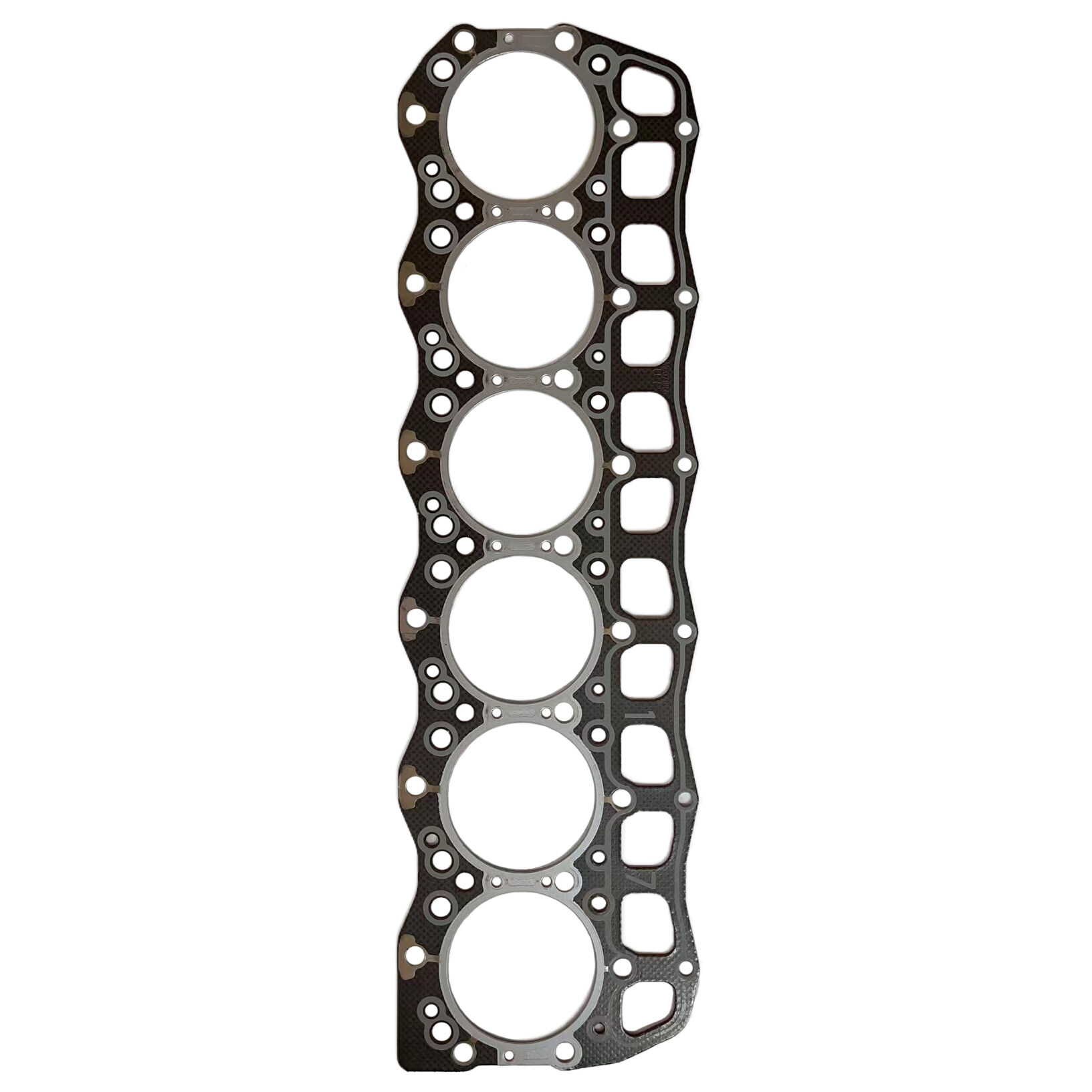

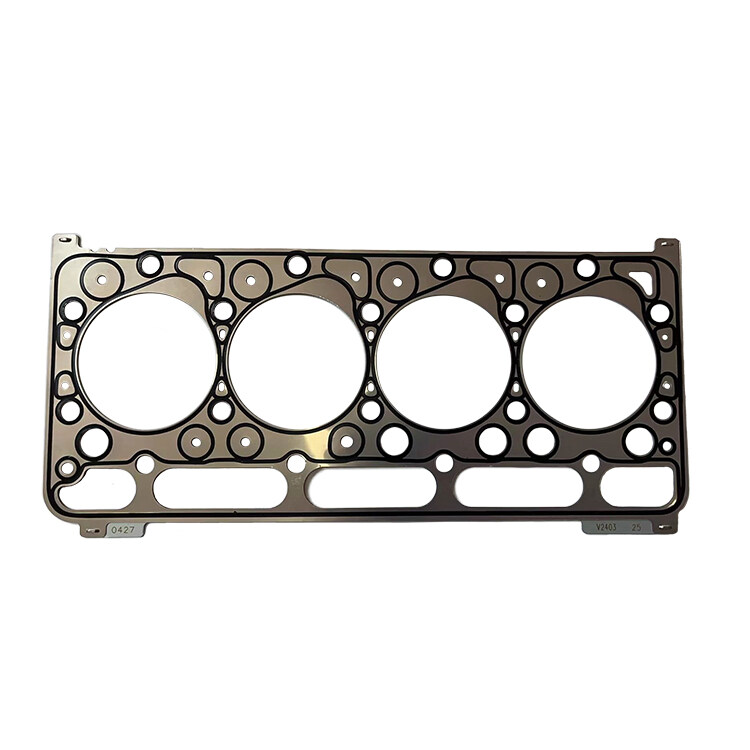

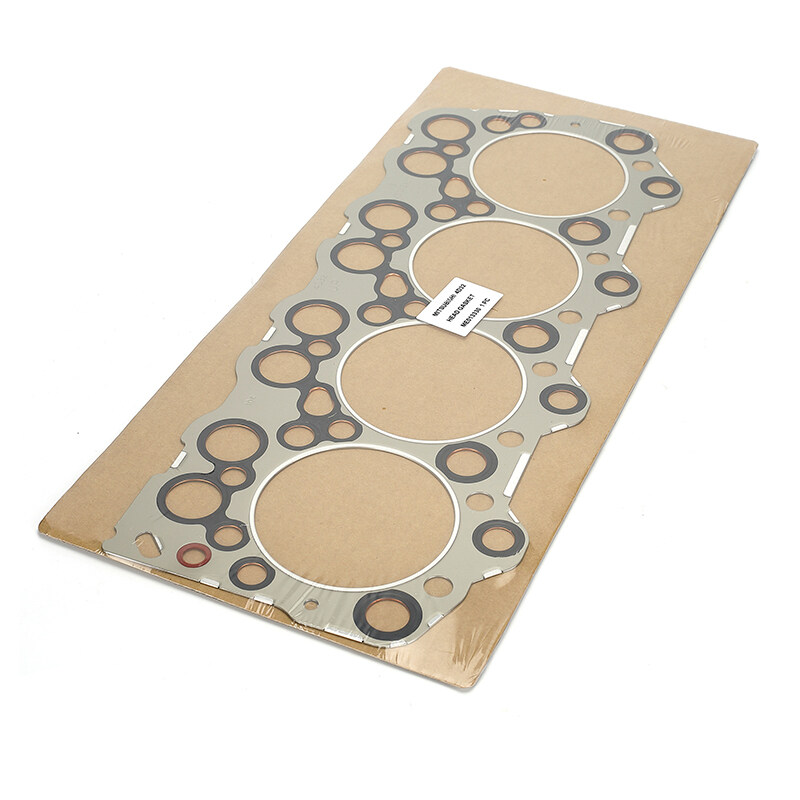

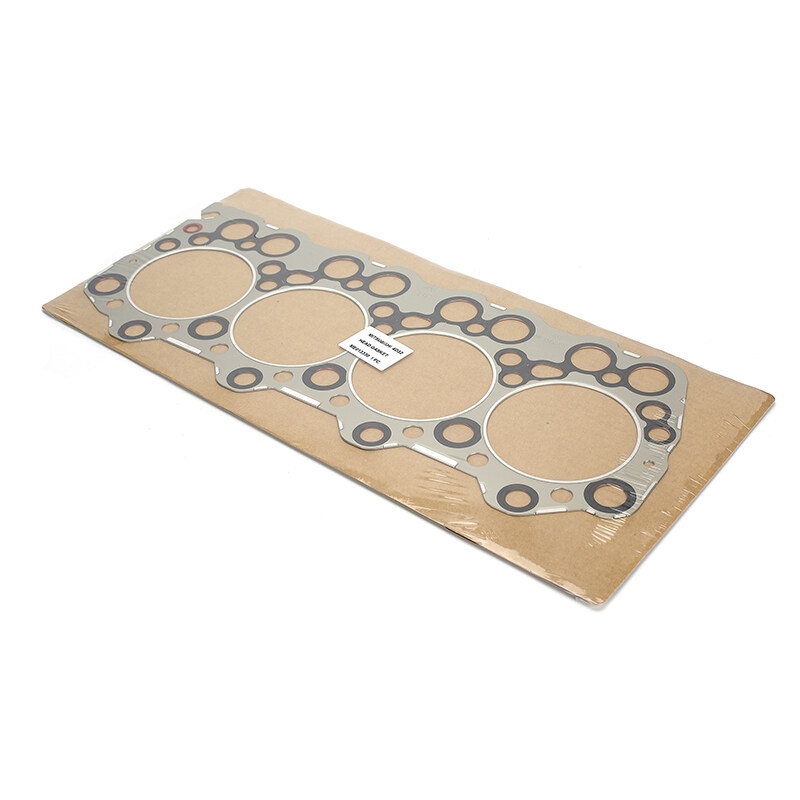

4d32 Engine Cylinder Head Gasket ME013330

The 4D32 engine cylinder head gasket is a vital component that seals the joint between the cylinder head and the engine block in a 4D32 engine. It plays a critical role in maintaining the integrity of the engine's combustion chamber, preventing the leakage of combustion gases, and ensuring the separation of oil and coolant passages.

Key Features and Functions:

-

Sealing: The primary function of the cylinder head gasket is to create a high-integrity seal between the cylinder head and the engine block. This seal is essential for maintaining proper compression, preventing the escape of combustion gases, and keeping oil and coolant passages separated.

-

Material: Cylinder head gaskets are typically made from high-quality materials, such as composite materials, multi-layer steel, or other advanced materials, to withstand the heat and pressure generated during combustion.

-

Design: The gasket is designed with openings and passageways to accommodate various components, such as the combustion chamber, water jackets for cooling, and oil passages for lubrication.

-

Sealing Rings: Some cylinder head gaskets have sealing rings or O-rings to further enhance the sealing capability.

Purchasing the 4D32 Engine Cylinder Head Gasket:

-

Identify the Correct Gasket: Ensure that you have the correct specifications and part number for the cylinder head gasket compatible with the 4D32 engine. You can find this information in the engine's manual or by consulting a reputable auto parts supplier.

-

Select a Reputable Supplier: Choose a reputable automotive parts supplier or manufacturer specializing in engine gaskets. You can find these suppliers through online research, contacting dealerships, or industry-specific distributors.

-

Request a Price Quote: Contact the supplier to request a price quote for the required quantity of cylinder head gaskets. Provide all necessary details, such as the make and model of the vehicle and any specific requirements.

-

Quality Assurance: Ensure that the gaskets meet the required quality standards and are designed to withstand the demands of the 4D32 engine.

-

Place Your Order: Once you are satisfied with a supplier's offer, place your order and clarify payment terms, delivery schedules, and any warranties or guarantees.

-

Payment: Make the necessary payment according to the agreed-upon terms.

-

Shipping and Delivery: Coordinate with the supplier for shipping and delivery to your location. Confirm shipping costs and delivery times.

-

Quality Control: Upon receiving the gaskets, inspect them for quality and ensure they match the required specifications for the 4D32 engine.

4D32 engine cylinder head gasket Product Parameter:

|

Product Name |

Cylinder Head Gasket |

|

Application |

Diesel Engine Parts |

|

Engine Number |

4D32 |

|

Size |

STD |

|

Material |

Steel |

|

OEM Number |

ME013330 |

|

Condition |

100% Brand-new |

|

Size |

Customized |

|

Payment Way |

T/T, L/C, Paypal, Western Union, UPS |

|

Car Model |

Mitsubishi |

|

Packing |

Neutral Packing |

The cylinder head gasket is a durable and high-quality steel component that can withstand extreme temperatures and pressures. Steel is a robust material with excellent wear-resistance, which significantly extends the gasket’s lifespan and reduces the cost of repairs and replacements. Additionally, it is easy to install, and professionals are not required to achieve optimal performance.

Pressure Resistance:

The cylinder head gasket of a diesel engine has excellent compressive strength to withstand the pressure generated during the engine’s operation. The gasket’s compressive strength is critical to ensure that it does not deform or rupture due to excessive pressure. The gasket is placed between the cylinder head and the engine block, and it must maintain a tight seal to prevent the leakage of gases and fluids. The compressive strength of the gasket is essential to maintain the seal and prevent any damage to the engine.

Oil Resistance:

The cylinder head gasket of a diesel engine has excellent oil resistance to prevent it from failing due to contact with diesel or lubricating oil. The gasket is placed between the cylinder head and the engine block, and it is exposed to various fluids during the engine’s operation. The gasket’s material has good oil resistance to ensure that it can withstand prolonged exposure to these fluids without degrading or losing its sealing properties. The gasket’s oil resistance is critical to prevent any leakage of fluids, which can cause engine damage and reduce its efficiency.

Excellent Elasticity:

The cylinder head gasket of a diesel engine has excellent elasticity to adapt to the changes that occur during the engine’s operation. The gasket is placed between the cylinder head and the engine block, and it must maintain a tight seal to prevent the leakage of gases and fluids. The gasket’s elasticity is critical to ensure that it can maintain a tight seal between the cylinder head and the engine block, even when there are changes in temperature, pressure, and other factors during the engine’s operation.

The role of the head gasket

Head gaskets are also referred to as washers and are often used to fasten components to the nut. The more common type is a thin sheet with an oval shape and a round hole in the middle, which is used to disperse the load on the nut and to reduce vibration and expand wear. Head gaskets are often used in the operation of machinery and equipment as a means of fastening and stabilizing.

Other important uses for head gaskets include rubber head gaskets or silicone head gaskets, which are also used to reduce the effects of vibration on fans and other equipment.

Material classification of head gaskets

There are many different types of head gaskets, but they are usually divided into three main categories: non-metallic head gaskets, semi-metallic head gaskets and metallic head gaskets.

Non-metallic head gaskets

Rubber head gaskets are non-metallic head gaskets. They are relatively soft and flexible and can be easily cut into different shapes for different applications. Due to the characteristics of rubber, rubber head gaskets are often used to seal pipes and vessels.

Asbestos-rubber head gaskets are also often used, as they can be made from a variety of different head gaskets with different strengths, elasticities and flexibilities depending on the ratio. These head gaskets are often used in the chemical industry.

Metal head gaskets

Metal head gaskets are available in copper, aluminium, mild steel, stainless steel, etc., and are usually used in high temperature and high pressure environments as well as in environments with high load carrying capacity. Metal head gaskets are available in flat metal head gaskets, waveform metal head gaskets and toothed metal gaskets depending on the shape of the environment. The choice is based on the structural characteristics of the head gasket. The flat metal head gasket is as narrow as possible.

How to replace the engine head gasket?

How to replace the engine gasket.

1. When the engine is cooling water, will involve the accessories of the cylinder head, such as the carburetor or electric injection accessories, pump, and tube, unlock, and its circuit as far as possible without moving.

2. If it is a top-mounted valve, remove the top cover, remove all the bolts on the cover, confirm that the bolts have been removed, tap the cylinder head with a hammer, and gently pry open the cylinder head with the starter and place it in a safe position.

3. Remove the cylinder gasket, gently brush the cylinder body (cylinder head) surface with a copper wire brush, confirm that the new cylinder gasket type is consistent, and properly placed, tighten the cylinder head in reverse order, pay attention to tighten the middle first, and then tighten both sides to ensure that the cylinder head is flat.

4. After all recovery can be the car to try, car hot and then tighten once, the first week of the hot car every day to tighten once, such as no abnormalities, valve foot clearance can be without adjustment, it is recommended to open the researchable valve, clear carbon and other maintenance.

The cylinder head bolts should be tightened evenly and alternately gradually to finally ensure the tightening torque, after installation to readjust the valve clearance. Engine cylinder head gasket, referred to as the cylinder gasket, is placed in the cylinder block and cylinder head between the elastic sealing components. As the cylinder block and cylinder head are between the absolute flat, therefore, need to have a cylinder headliner to prevent high pressure gas, lubricating oil, and cooling water from between them out.